Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

A professional guide to the lifecycle of a glass jar, covering batching, melting, forming, annealing, and the rigorous quality control standards at XUZHOU TROY.

Have you ever wondered how a handful of sand transforms into a perfectly clear, durable Mason jar? At XUZHOU TROY, glassmaking is a harmonious blend of ancient elemental science and cutting-edge industrial technology. For our B2B partners, understanding this journey is key to appreciating the strength, safety, and brilliance of our packaging solutions.

The journey begins with the selection of high-purity raw materials. Our “recipe” consists primarily of silica sand, soda ash, and limestone. These are meticulously weighed and mixed with cullet (recycled glass). Using cullet not only conserves energy but also reinforces our commitment to sustainable manufacturing.

Cullet (recycled glass) is an excellent raw material. Its melting point is significantly lower than that of virgin materials (such as quartz sand, soda ash, limestone, etc.), leading to a substantial reduction in fuel consumption (approximately 10%-30% energy savings), decreased consumption of virgin materials, and lower carbon emissions. It represents a typical model of circular economy.

A higher proportion of cullet results in lower production costs and greater environmental benefits. Therefore, manufacturers are motivated to increase the usage ratio of cullet as much as technically feasible.

Glass Composition Stability: The source and quality of the cullet are crucial. For food bottle manufacturers, the primary source of cullet is the defective products and trimmings generated on their own production lines (referred to as “in-house returns” or “revert”). Its composition is identical to the target product, making it the purest and most controllable in quality, allowing for high-percentage or even 100% reuse.

External Cullet: If cullet is procured from external social recycling streams, it must undergo extremely rigorous sorting, cleaning, and inspection to ensure it is free from impurities, heavy metals, foreign materials like ceramics or stones, and that its chemical composition matches the production formula. For food packaging applications, the requirements for external cullet are extremely stringent, and its usage ratio is strictly controlled to prevent contamination.

Color Requirements: For high-clarity or crystal-clear transparent bottles, which have strict requirements on indicators like iron content, using mixed-color cullet can severely affect color and transparency. Therefore, the cullet ratio for such bottles might be maintained at a lower level (e.g., 30%-40%), and the cullet must come from a single, pure source. Ordinary soda-lime glass bottles can tolerate a higher proportion of cullet.

Different types of furnaces (electric furnaces, gas-fired furnaces) have varying adaptability to high cullet ratios.

An excessively high cullet ratio may affect the homogeneity of the glass melt and the melting process, placing higher demands on production line control.

The batch is fed into our high-capacity furnaces, where temperatures soar to a staggering 1500°C (2700°F). At this heat, the solid mixture transforms into a glowing, molten liquid. Our engineers monitor the furnace 24/7 to ensure the glass reaches a state of perfect homogenization, free from impurities or air bubbles.

Once the molten glass reaches the ideal viscosity, it is cut into precise “gobs”—glowing drops of liquid glass. These gobs are fed into an IS (Individual Section) Machine. Depending on the design, we use two primary methods:

Blow-and-Blow: Used for narrow-neck bottles.

Press-and-Blow: The standard for our famous Mason jars, ensuring uniform wall thickness and a wide, reinforced mouth.

As the jars leave the mold, they are still red-hot. If they cool too quickly, they will shatter due to internal thermal stress. To prevent this, the jars enter the Annealing Lehr—a long, temperature-controlled tunnel. Here, they are reheated and then slowly cooled, a critical process that gives XUZHOU TROY glass its legendary durability and impact resistance.

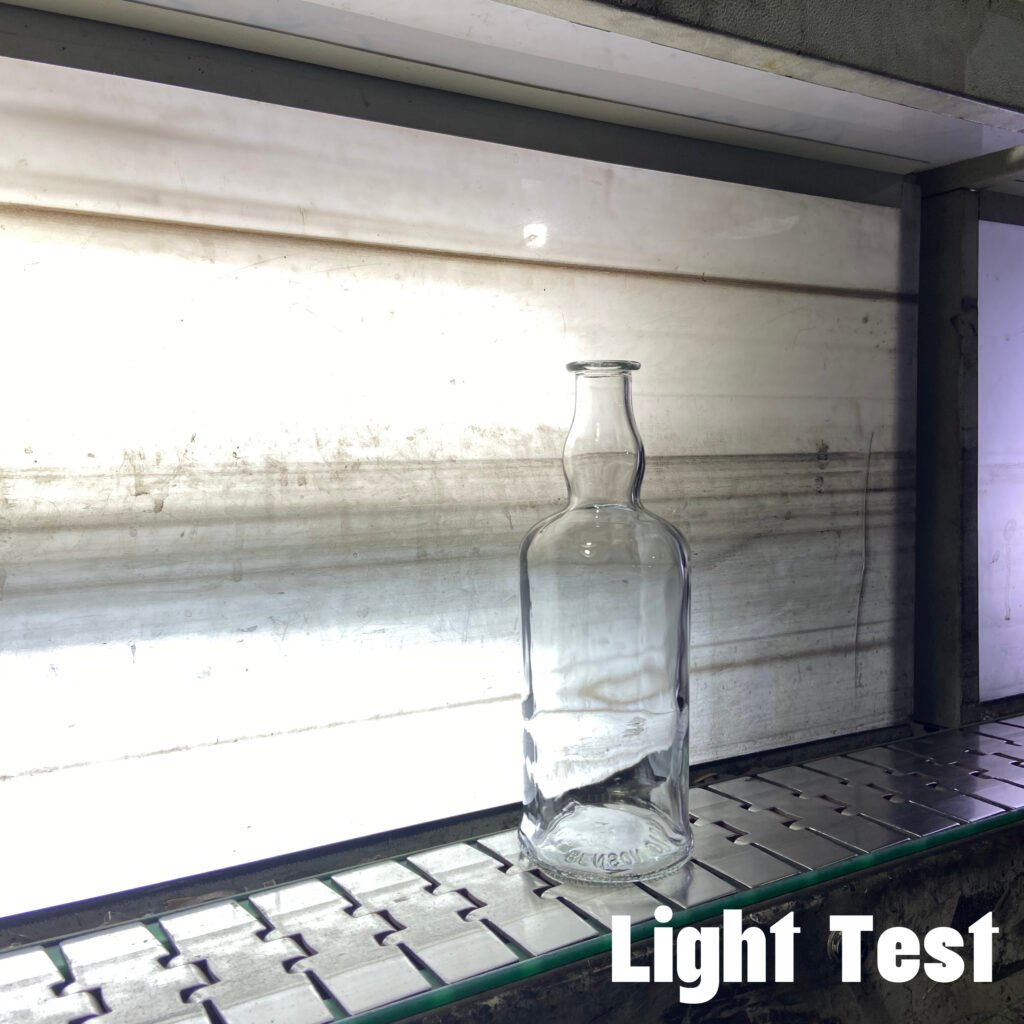

Quality is not an afterthought; it is integrated into every step. After annealing, every jar undergoes a series of rigorous checks:

Pressure & Thermal Shock Testing: Ensuring the jars can withstand canning processes and temperature swings.

Manual Sampling: Our QC experts perform hands-on checks for thread precision and aesthetic clarity.

For clients seeking a unique brand identity, this is where the magic happens. After the base jar is formed, we offer secondary treatments including screen printing, frosting, electroplating, and precision color spraying. This transforms a standard container into a bespoke piece of brand equity.

Producing glass is a demanding discipline that leaves no room for error. At XUZHOU TROY, we pride ourselves on mastering this complex flow—from the raw sand to the final polished product on your shelf. When you choose our glass packaging, you are choosing a product forged in fire and refined by technology.

CONTACT OUR TEAM >>