Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

This article explains how automated silk screen printing transforms glass packaging through precision engineering, offering durability, batch consistency, cost efficiency, and versatile creative options for brands across industries.

To many, silk screen printing on glass packaging appears as a simple decorative step—a means to apply a logo or basic design. However, in the realm of precision manufacturing, modern automated silk screen printing represents a sophisticated engineering discipline that delivers measurable, strategic value far beyond aesthetics. At XUZHOU TROY, we leverage this technology not merely to decorate, but to engineer packaging that enhances brand equity, ensures durability, and streamlines operations. Here’s a deep dive into how automated silk screen printing transforms your glass containers into superior brand assets.

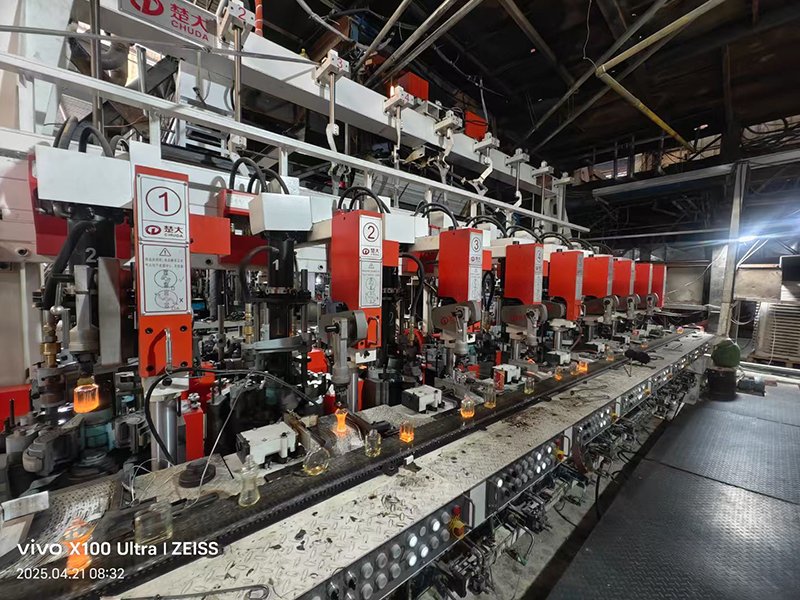

Automated silk screen printing is a high-speed, digitally controlled process where specialized inks are precisely forced through a fine, patterned mesh screen onto the substrate. Robotic arms handle the glass with sub-millimeter accuracy, ensuring perfect positioning for each print cycle. Unlike manual or semi-automated methods, every variable—from ink viscosity and squeegee pressure to curing time and registration—is managed by programmable logic controllers. This transforms printing from a craft into a repeatable science, guaranteeing uniformity at a scale impossible to achieve by hand.

A brand’s visual identity must endure the rigors of the real world. Automated silk screen printing creates a permanent bond between ink and glass.

Engineered for Survival: Our prints are rigorously tested to withstand industry-standard challenges: repeated exposure to 70% isopropyl alcohol (simulating sanitizer spills), 500+ cycles of mechanical friction (simulating transport scuffing), and condensation washing (simulating refrigerator and dishwasher environments)—all without cracking, peeling, or fading.

Consistent Brand Experience: This durability ensures your logo, colors, and typography arrive at the point of sale—and remain in the consumer’s home—exactly as designed. The brand promise is preserved from production line to final use, protecting your investment in packaging and marketing.

Brands demand perfection, especially on premium packaging. Automation delivers it consistently.

Micro-Detail Capability: Advanced screens and controls can reproduce exceptionally fine details, including line widths as narrow as 0.2mm and highly intricate patterns. This allows for sophisticated design elements that convey luxury and attention to detail.

Absolute Batch-to-Batch Consistency: Digital setup files eliminate human variables. Whether you run 10,000 or 10 million units, the color density, registration (alignment), and clarity of the print remain identical. This eradicates the “color drift” and positioning errors common in manual processes, ensuring a uniform brand presentation worldwide.

Automation drives value by optimizing resources and reducing waste.

Radically Reduced Material Waste: Automated, closed-loop ink dispensing systems achieve a material utilization rate exceeding 99.5%. Precise application means almost every gram of ink ends up on the product, not as waste in screens or on the shop floor.

Optimized Labor and Throughput: One fully automated printing line can achieve the output of 15-20 manual workstations with a fraction of the personnel, significantly reducing labor costs and human error. It also enables high-speed production of 60-120 units per minute, seamlessly integrating with fast-paced filling lines.

The technology adapts to your vision, not the other way around.

Multi-Substrate Compatibility: The process is expertly tuned for glass but is equally effective on ceramics and metals, offering flexibility for diverse product lines or multi-material packaging components.

Advanced Special Effects: Move beyond standard colors. We incorporate metallic and pearlescent inks for luxury shimmer, textured or raised printing (simulating embossing) for tactile engagement, and even UV-reactive or glow-in-the-dark pigments for innovative branding and functional night-time visibility.

Speed and flexibility are critical in modern manufacturing.

Rapid Changeover for SKU Diversity: Digital job storage allows for swift transitions between different bottle designs or label information. Line changeover times can be reduced to 15 minutes or less, enabling cost-effective production of small batches and limited editions without sacrificing efficiency.

Reliable High-Volume Output: The combination of speed and consistency makes automated silk screening the ideal solution for large-scale runs, providing predictable lead times and reliable capacity for global product launches.

Cosmetics & Fragrance: Permanent, luxurious branding on perfume flacons, serum bottles, and cream jars that resists handling and essential oils.

Premium Beverages: Durable application of batch codes, regulatory markings, and elegant designs on spirit bottles, where condensation and handling are constant factors.

Pharmaceuticals & Nutraceuticals: Clear, tamper-evident printing of safety warnings, dosage instructions, and logos on vials and jars, ensuring critical information remains legible.

A leading luxury skincare brand faced challenges with their previous hot-stamping decoration: an 8% defect rate (smudging, misalignment) and high per-unit costs. By partnering with XUZHOU TROY and transitioning to our automated silk screen printing line, they achieved transformative results:

Defect Rate Plummeted to 0.3%, dramatically improving quality and reducing waste.

Decoration Costs Were Reduced by 40% through higher material efficiency and lower labor overhead.

Brand Perception Elevated due to the superior, more consistent tactile and visual quality of the print.

Our commitment goes beyond operating machinery. We provide a partnership grounded in technical expertise:

Pre-Production Consulting: We analyze your glass geometry and design to engineer the optimal print setup.

Ink Chemistry Expertise: We develop or source inks formulated for specific adhesion, finish, and resistance requirements.

End-to-End Quality Assurance: Every run is monitored by vision systems and sampling protocols to guarantee the output meets our stringent standards.

Automated silk screen printing is the intersection where brand ambition meets manufacturing excellence. It’s the assurance that your packaging’s first impression is perfect and that its quality endures.

REQUEST FREE SAMPLES NOW >>

CONTACT OUR TEAM >>

FIND MORE PRODUCTION VIDEOS >>