Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

A comprehensive guide from Xuzhou Troy explaining the three key color grades of clear soda-lime glass for packaging: Flint, Clear, and Ultra-Clear. Learn how iron content and processing affect clarity, cost, and brand perception to make the perfect choice for your product.

In the world of premium spirits, gourmet foods, and artisanal products, packaging is far more than a container—it’s a critical expression of your brand’s quality and values. Glass remains the material of choice for discerning brands, offering unmatched clarity, product integrity, sustainability, and timeless appeal. However, not all “clear” glass is created equal.

At Xuzhou Troy, we specialize in high-quality glass packaging solutions. A cornerstone of our expertise is soda-lime glass—the most versatile and widely used type for bottles and jars. While often grouped under one term, significant variations in clarity directly impact aesthetics, functionality, and cost.

This guide demystifies the three primary grades of clear soda-lime glass: Flint, Clear (Extra-Clear), and Ultra-Clear. Understanding these distinctions empowers you to make an informed choice that aligns perfectly with your product positioning, target market, and brand vision.

Soda-lime glass is composed primarily of silica sand (~70-75%), soda ash (~12-16%), and limestone (~10-15%). Celebrated for its excellent chemical stability, formability, and cost-effectiveness, it is the industry standard for most glass packaging, from everyday items to luxury goods.

The journey from a standard container to a brilliant showcase begins with the purity of raw materials and precision in manufacturing.

Visual Characteristic: Exhibits a noticeable greenish or bluish-green tint, especially visible at the bottle’s edges or in thicker sections. This is the natural color of untreated soda-lime glass.

The Cause: The tint comes from iron oxide impurities (Fe²⁺/Fe³⁺) naturally present in raw materials.

Applications & Brand Fit: The most economical choice, ideal for cost-sensitive packaging where ultimate clarity is not critical. Perfect for standard beer bottles, table wines, value spirits, cooking oils, and mass-market products. Its robustness and 100% recyclability make it a practical, sustainable workhorse.

Ideal For: Brands prioritizing functionality, efficiency, and value, especially for darker-colored contents where the tint is less noticeable.

Visual Characteristic: Appears significantly whiter and brighter than flint glass. It offers reduced green tint, higher light transmission, and provides a more neutral, premium backdrop for your product.

The Cause: Achieved by using raw materials with lower iron content and adding decolorizing agents (e.g., Selenium) during melting to neutralize the greenish hue.

Applications & Brand Fit: The preferred choice for premium packaging where accurate product color and enhanced presentation are important. Commonly used for spirits, perfumes, high-end foods, pharmaceutical bottles, and milk.

Ideal For: Brands seeking a balance between cost and a elevated, clean aesthetic. It enhances shelf appeal and is excellent for products where color fidelity matters.

Visual Characteristic: Represents the pinnacle of clarity—virtually colorless with exceptional brilliance and very high light transmission (often >91%). It rivals crystal, offering a pristine, undistorted view of the contents.

The Cause: Requires ultra-low iron raw materials (iron content below 0.015%) and precisely controlled melting conditions with advanced refining agents to eliminate color-causing impurities.

Applications & Brand Fit: Reserved for luxury and high-value products where supreme visual impact is non-negotiable. The standard for top-shelf spirits, premium cosmetics, fine fragrances, gourmet oils, and gift-ready packaging.

Ideal For: Brands where packaging is a central part of the luxury experience. It maximizes perceived value, showcases product purity, and is highly compatible with sophisticated decoration techniques like embossing and intricate printing.

| Feature | Flint Glass (Standard) | Clear Glass (Extra-Clear) | Ultra-Clear Glass (High Flint) |

|---|---|---|---|

| Clarity & Color | Noticeable green/blue tint | White, bright, low tint | Colorless, crystal-clear brilliance |

| Primary Driver | Natural iron impurities | Use of decolorizers; lower-iron materials | Ultra-pure, ultra-low iron materials |

| Cost | Most economical, budget-friendly | Moderate, balanced investment | Premium, higher-quality investment |

| Best For | Value, mass-market, & dark liquids | Premium positioning & color fidelity | Luxury, prestige, & maximum visual impact |

| Brand Impression | Practical, reliable, sustainable | Clean, premium, trustworthy | Elegant, sophisticated, high-value |

| Sustainability | 100% Recyclable | 100% Recyclable | 100% Recyclable |

The choice between Flint, Clear, and Ultra-Clear glass hinges on aligning material properties with your brand strategy. Consider these questions:

Market Position: Is your product mass-market, premium, or luxury?

Visual Impact: How critical is perfect clarity to your product’s shelf appeal and consumer perception?

Contents: Are you packaging a dark liquid (where tint matters less) or a clear, light one (where clarity is key)?

Budget: What is the optimal balance between packaging cost and the value it adds to your brand?

In short:

Choose Flint Glass for robust, cost-effective, and sustainable packaging.

Choose Clear Glass for a marked step up in presentation and premium feel.

Choose Ultra-Clear Glass for unmatched brilliance and a definitive luxury statement.

| Feature | Decal Printing | Screen Printing | Direct Ceramic Printing |

|---|---|---|---|

| Color Capacity | Unlimited colors | 1-3 colors typically | 4-6 colors |

| Design Complexity | Photographic quality | Simple graphics | Moderate complexity |

| Surface Coverage | Full 360° possible | Limited areas | Full coverage available |

| Metallic Effects | Excellent | Limited | Good |

| Cost Efficiency | Premium | Economical | Moderate |

| Minimum Order | 1,000+ units | 5,000+ units | 10,000+ units |

| Lead Time | 4-6 weeks | 3-4 weeks | 5-7 weeks |

At Xuzhou Troy, we don’t just manufacture glass—we craft packaging solutions that tell your brand’s story. Our mastery spans all three grades of soda-lime glass, ensuring we can recommend and produce the perfect option for your needs.

End-to-End Expertise: From initial design consultation and mold manufacturing to precision forming and expert decoration, we maintain full control over quality and timelines.

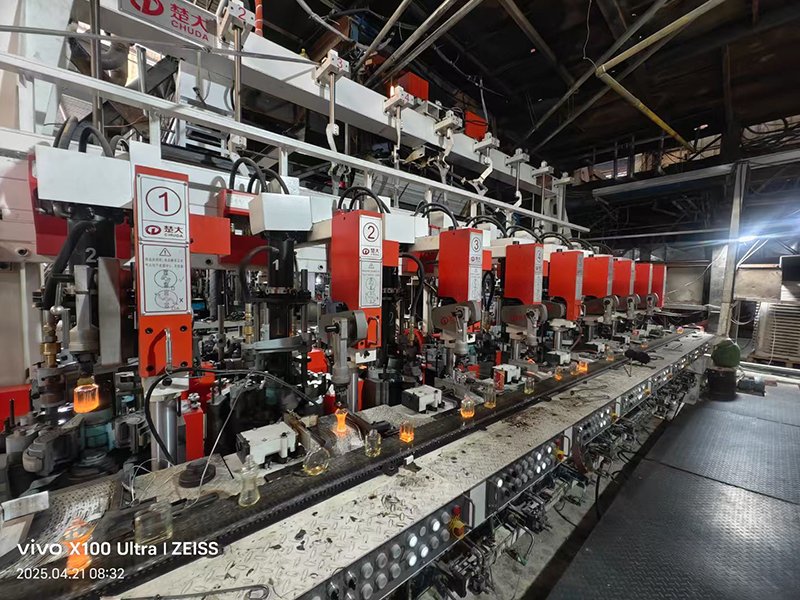

Advanced Technology: We invest in state-of-the-art production and inspection technology to ensure consistency, clarity, and excellence in every bottle, regardless of grade.

Sustainable Focus: We champion glass as the ultimate sustainable packaging material and optimize our processes for energy efficiency and closed-loop recycling support.

Global Capability, Local Partnership: We serve clients worldwide, offering scalable production and responsive, collaborative service tailored to your specific market goals.

Whether you’re launching a craft spirit, elevating a gourmet food line, or developing a new cosmetic range, the right glass is foundational to your success.

Contact Xuzhou Troy today to discuss how our expertise in flint, clear, and ultra-clear soda-lime glass can create packaging that protects your product, captivates your customers, and authentically represents your brand’s commitment to excellence.

CONTACT OUR TEAM >>