Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

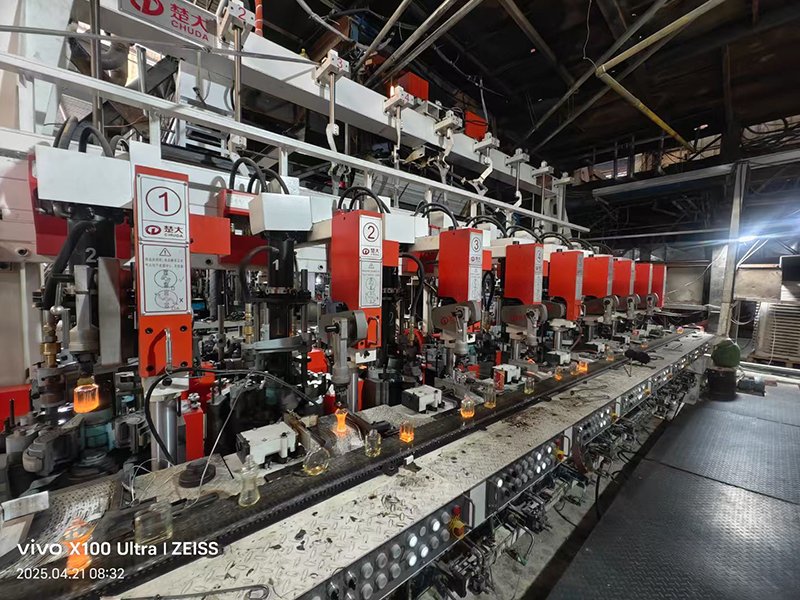

This article delves into the key factors affecting the surface smoothness of glass liquor bottles during production and provides actionable strategies for prevention. From raw material quality and mold maintenance to forming parameters and handling processes, learn how to achieve superior finish and reduce defects in high-end packaging.

The surface smoothness of glass liquor bottles is crucial to their appearance, directly impacting brand image and consumer perception. This article analyzes key factors that compromise the smoothness of glass bottles during production and provides corresponding preventive measures.

These factors span the entire process from raw materials to production and annealing.

Factors: Excessive refractory impurities (such as chromite or alumina particles) in raw materials (quartz sand, soda ash, limestone, cullet, etc.) or uneven mixing can lead to stones, streaks, and bubbles in the molten glass. These defects manifest as bumps, pits, or localized cloudiness on the bottle surface.

Manifestations: Tiny hard particles, linear textures, or pinholes appear on the bottle.

This is the most critical factor affecting surface finish.

Rough or Damaged Mold Surface: Insufficient polishing of new molds or scratches, corrosion, and carbon buildup (from oxidized lubricants) on used molds.

Improper Mold Temperature: Overheated molds can cause glass sticking, resulting in a rough, “peeling” surface; overly cold molds cause the glass to set too quickly, leading to wrinkles or cold spots.

Failed/Uneven Mold Coating: Peeling or uneven high-temperature coatings (e.g., silicon carbide, graphite) on the mold interior cause direct contact between the glass and metal, leading to localized adhesion and surface defects.

Poor Mold Cleanliness: Excessive or accumulated release agents, dust, or residual glass碎片 can imprint on the bottle.

Unstable Gob Temperature and Weight: Excessive temperature makes the glass too “soft,” prone to sticking; insufficient temperature reduces fluidity, resulting in poor surface formation and prominent seam lines. Weight variations cause inconsistent bottle shape and uneven wall thickness.

Improper Pressing/Blowing Pressure and Timing: Insufficient pressure or time prevents the glass from fully conforming to the mold, causing blurred details or a hazy surface. Excessive pressure can exaggerate the “mold seam” or create thin spots.

Uncoordinated IS Machine Rhythm: Unsteady transfer, inversion, or mold opening/closing actions can cause scratches or deformation.

Improper Annealing Temperature Curve: While annealing primarily relieves internal stress, excessively high temperatures or prolonged times can cause surface re-oxidation or “blooming,” forming a frost-like haze that dulls the gloss.

Poor Annealing Lehr Cleanliness: Dust or particles from refractory materials falling onto hot bottles can adhere, creating blemishes.

Bottle-to-Bottle Collisions: Hard impacts during hot-end transfer, cold-end conveying, and inspection/packaging lines cause scratches and abrasions (known as “conveyor marks”).

Worn Contact Points: Abrasions or burrs on pushers, conveyor belts, or star wheels scratch bottles at specific contact points.

Corresponding strategies require a systematic management approach.

Use high-purity, consistently supplied raw materials.

Optimize batch formulas and mixing processes for uniformity.

Strictly control furnace temperature and atmosphere to improve glass homogeneity and fining, reducing seeds and impurities.

Mold Manufacturing and Maintenance: Employ high-precision machining and polishing to achieve a mirror-like finish inside the mold cavity. Establish regular maintenance, repair, and replacement schedules.

Precise Mold Temperature Control: Use closed-loop cooling systems with sensors to monitor temperatures across different zones, maintaining the mold within an optimal, stable range.

Optimized Coating Application: Apply high-performance mold coatings regularly and evenly, inspecting for adhesion and integrity.

Standardized Cleaning: Implement strict mold cleaning procedures using appropriate tools and agents to prevent oil residue and carbon buildup.

Stabilize the Gob: Precisely control forehearth temperature and shearing mechanisms to ensure consistent gob weight and temperature.

Parameter Refinement: Use Design of Experiments (DOE) to identify and lock in optimal pressing/blowing pressure, timing, air volume, etc.

Equipment Maintenance: Regularly inspect the mechanical actions, pneumatic system stability, and synchronization of the IS machine for smooth operation.

Develop Scientific Annealing Curves: Set appropriate temperatures and durations for heating, holding, slow cooling, and rapid cooling stages based on bottle thickness and glass composition to prevent surface devitrification.

Maintain Lehr Cleanliness: Regularly clean annealing lehrs.

Minimize Mechanical Contact Damage:

Use gentle-contact materials (e.g., PTFE-coated guides, star wheels) on hot and cold ends.

Optimize conveyor speed and layout to reduce bottlenecks and impact points.

Install padding at key contact points.

Train operators in careful handling practices.

Inspection: Labor inspection at the line end to detect surface defects (scratches, bumps, bubbles, etc.) and reject non-conforming products in real time.

Offline Sampling: Conduct regular inspections

In summary, achieving high-smoothness glass liquor bottles requires a systematic approach based on four pillars: consistent high-quality materials, precise and well-maintained molds, accurately controlled processes, and gentle, standardized handling. Among these, mold condition and temperature control are central, while standardized process management and preventive maintenance throughout the production line are essential for sustaining high quality. Continuous investment and technical optimization in these areas enable manufacturers to significantly enhance the visual appeal and yield rates of glass bottles.

CONTACT OUR TEAM >>