Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

This comprehensive guide explores decal printing as an advanced decoration method for glass bottles, highlighting its ability to create complex multi-color designs, metallic effects, and full-wrap graphics. The article covers the technical process from design optimization to kiln firing, compares decal printing with other methods, and demonstrates XUZHOU TROY's expertise in producing premium, durable surface decorations for various industries.

In the competitive world of product packaging, surface decoration often determines whether a glass bottle gets noticed or overlooked. While various printing methods exist, decal printing stands out as a premium solution for achieving complex, multi-colored designs with exceptional durability. At XUZHOU TROY, we specialize in transforming glass containers into distinctive brand canvases through advanced decal application techniques.

Decal printing, derived from the French term décalcomanie, involves transferring pre-printed designs from a specialized substrate onto glass surfaces using heat or water activation. Unlike direct printing methods, decals allow for intricate multi-color graphics, metallic effects, and photographic-quality imagery that would be challenging with traditional screen printing.

This centuries-old technique has evolved into a sophisticated process that combines artistic expression with technical precision, creating durable decorations that withstand handling, washing, and environmental exposure.

Decal printing excels where other methods face limitations:

Full-color reproduction including gradients and photographic images

Metallic effects using gold, silver, and other specialty foils

Intricate details with precise registration

360-degree coverage for complete bottle decoration

Our decal technology accommodates diverse container geometries:

Round, square, triangular, and irregular shapes

Curved surfaces and hard-to-reach areas

Various bottle sizes from miniatures to large-format containers

Properly applied and fired decals become permanently fused with the glass surface, offering:

Resistance to abrasion, moisture, and chemical exposure

Dishwasher safety for food and beverage containers

Long-term color stability without fading or peeling

Decals create a seamless, integrated appearance that elevates perceived product value through:

Smooth, edge-free application

High-gloss or matte finish options

Tactile texture possibilities

Phase 1: Design Optimization

Before production begins, our design team collaborates with clients to ensure artwork translates effectively to the decal medium. We focus on:

Visual hierarchy that communicates brand messaging clearly

Color optimization for vibrant post-firing results

Technical adaptation to specific bottle contours and dimensions

Regulatory compliance for required product information

Phase 2: Decal Production

Using specialized ceramic inks and substrates, we create precision decals featuring:

Multiple color layers with exact registration

Specialty finishes including metallic, pearlescent, and textured effects

Custom sizing tailored to each container’s dimensions

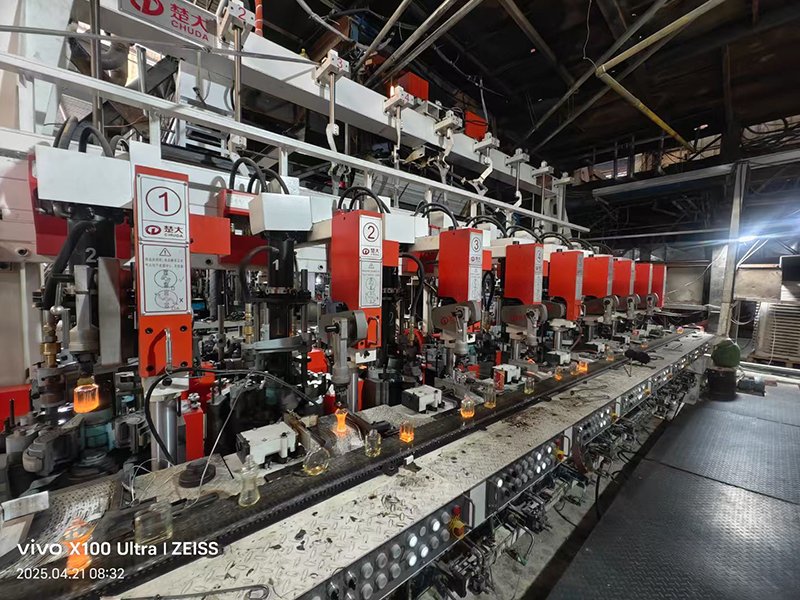

Phase 3: Application and Firing

Our controlled application process ensures flawless results:

Surface Preparation: Glass bottles undergo thorough cleaning and pre-treatment

Water-Slide Application: Decals are precisely positioned using our water-transfer technique

Drying Period: 24-hour controlled drying ensures proper adhesion

Kiln Firing: High-temperature firing (typically 550-600°C) permanently fuses decoration to glass

Quality Verification: Each piece undergoes inspection for clarity, alignment, and durability

| Feature | Decal Printing | Screen Printing | Direct Ceramic Printing |

|---|---|---|---|

| Color Capacity | Unlimited colors | 1-3 colors typically | 4-6 colors |

| Design Complexity | Photographic quality | Simple graphics | Moderate complexity |

| Surface Coverage | Full 360° possible | Limited areas | Full coverage available |

| Metallic Effects | Excellent | Limited | Good |

| Cost Efficiency | Premium | Economical | Moderate |

| Minimum Order | 1,000+ units | 5,000+ units | 10,000+ units |

| Lead Time | 4-6 weeks | 3-4 weeks | 5-7 weeks |

When to Choose Decal Printing:

Products requiring premium positioning

Complex branding with multiple colors or effects

Limited edition or specialty releases

Containers with challenging geometries

Applications requiring maximum durability

Premium Beverages

Limited edition spirit bottles with elaborate designs

Craft beer containers with full-wrap graphics

Specialty beverage packaging requiring photographic elements

Cosmetics & Fragrances

Luxury perfume bottles with intricate patterns

Skincare containers with metallic brand elements

Gift editions requiring special decoration

Food & Gourmet Products

Artisanal condiment bottles with recipe graphics

Premium oil containers with regional imagery

Specialty food packaging telling product stories

Pharmaceutical & Nutraceutical

High-end supplement bottles with detailed usage graphics

Medical containers requiring precise color coding

Professional healthcare packaging

Home & Lifestyle

Decorative candle holders with patterned designs

Premium kitchenware with artistic elements

Collectible containers with commemorative graphics

Decal printing represents the intersection of artistic expression and technical precision in glass decoration. While not the solution for every application, it provides unparalleled capabilities for brands seeking to create truly distinctive packaging that tells compelling visual stories.

At XUZHOU TROY, we view decal printing not merely as a decoration process, but as a brand enhancement tool. By permanently integrating sophisticated designs into glass surfaces, we help products command attention, communicate quality, and create lasting brand impressions.

CONTACT OUR TEAM >>