Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

For procurement professionals, understanding how a product is made is key to assessing its quality, consistency, and value. A glass jar may seem simple, but its creation is a fascinating blend of ancient art and modern precision engineering.

At Xuzhou Troy, we believe transparency builds trust. We invite you on a journey through our state-of-the-art manufacturing process, where we transform raw materials into the premium glass jars you rely on for your products.

This type of glass is the industry standard for food and drink containers due to its excellent chemical stability, clarity, and strength.

Every superior glass jar starts with a precise recipe. The process begins in the batch house, where raw materials are carefully weighed and mixed.

Silica Sand: The primary component (over 70%), providing the glass’s structure.

Soda Ash: Lowers the melting temperature, making the process more energy-efficient.

Limestone: Enhances the chemical durability and hardness of the final product.

Cullet (Recycled Glass): We integrate a high percentage of recycled glass (cullet) into our batch. This not only makes our process more sustainable but also lowers the required melting temperature, reducing our carbon footprint.

| Raw Material | Chemical Formula | Typical Percentage by Weight (%) | Primary Function in Glass |

|---|---|---|---|

| Silica Sand | SiO₂ | 68% – 73% | Glass Former: The primary network former. Provides structural integrity, hardness, and chemical resistance. |

| Soda Ash | Na₂CO₃ | 12% – 15% | Flux: Lowers the melting point of silica significantly, reducing energy consumption during production. |

| Limestone / Dolomite | CaCO₃ / CaMg(CO₃)₂ | 10% – 13% | Stabilizer: Imparts durability, hardness, and resistance to weathering. Prevents water solubility. |

| Alumina | Al₂O₃ | 1.5% – 2.5% | Stabilizer & Viscosity Modifier: Enhances chemical durability, improves mechanical strength, and prevents devitrification (crystallization). |

| Cullet (Recycled Glass) | – | 25% – 60% (in batch) | Key Ingredient: Lowers melting temperature and energy use, reduces raw material consumption, and decreases CO₂ emissions. |

| Refining Agents | e.g., Na₂SO₄ | 0.2% – 0.5% | Debubbling: Helps remove gas bubbles (seeds and blisters) from the molten glass to ensure clarity and strength. |

| Colorants/Decolorizers | Various | < 1% | Color Control: Added in minute quantities to create specific colors or to neutralize the natural greenish tint of iron impurities. |

Cullet (Recycled Glass): This is a crucial component in modern glass manufacturing. The high percentage of Cullet is a hallmark of sustainable modern glass production. The exact amount varies by manufacturer and region but is a major component of the batch.

Chemical Stability: The combination of Silica, Lime, and Alumina creates a glass that is highly inert. This prevents interactions with the food or beverage, preserving taste and safety.

Color Variations:

Flint (Clear) Glass: Uses decolorizers like Selenium (Se) and Cobalt Oxide (Co₃O₄) to counteract the green tint from iron impurities.

Amber (Brown) Glass: Created by adding a combination of Iron Sulfide and Carbon. It protects light-sensitive contents (e.g., beer, certain pharmaceuticals).

Green Glass: Achieved with higher levels of Iron Oxide (Fe₂O₃) or Chromium Oxide (Cr₂O₃). Commonly used for wine and some soft drinks.

Variations: The exact percentages can vary slightly depending on the specific manufacturing plant, the desired properties of the final product (e.g., resistance to internal pressure), and the source of the raw materials.

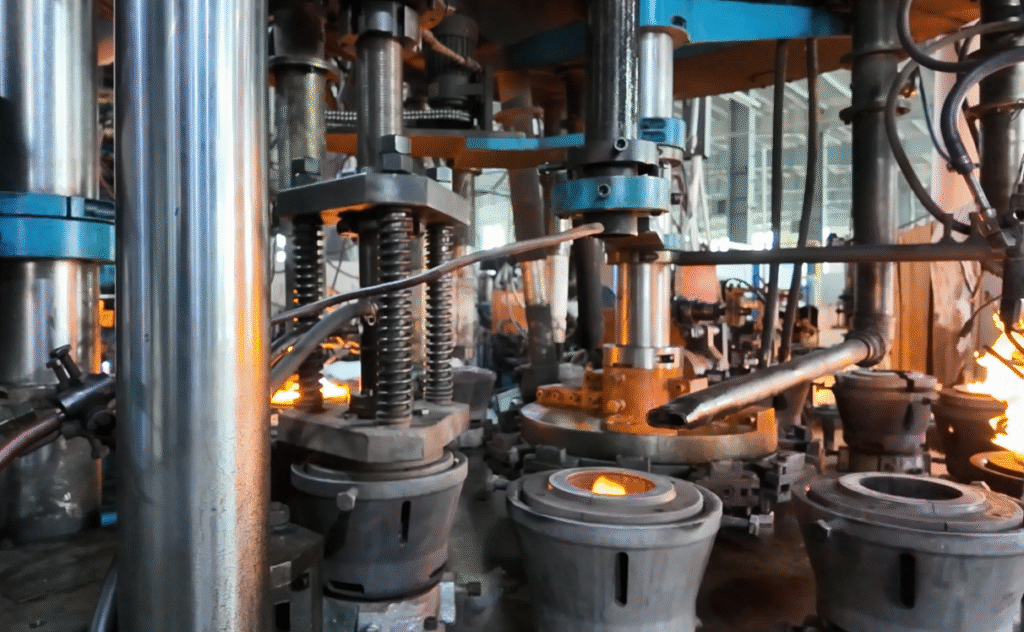

The mixed batch is fed into a regenerative furnace, which operates 24/7 at temperatures soaring to 1600°C (2900°F). In this intense heat, the raw materials fuse into a homogeneous, molten glass ready for forming.

Xuzhou Troy’s Commitment: Our advanced furnaces are equipped with sophisticated environmental controls to minimize emissions and maximize energy efficiency, reflecting our dedication to sustainable manufacturing.

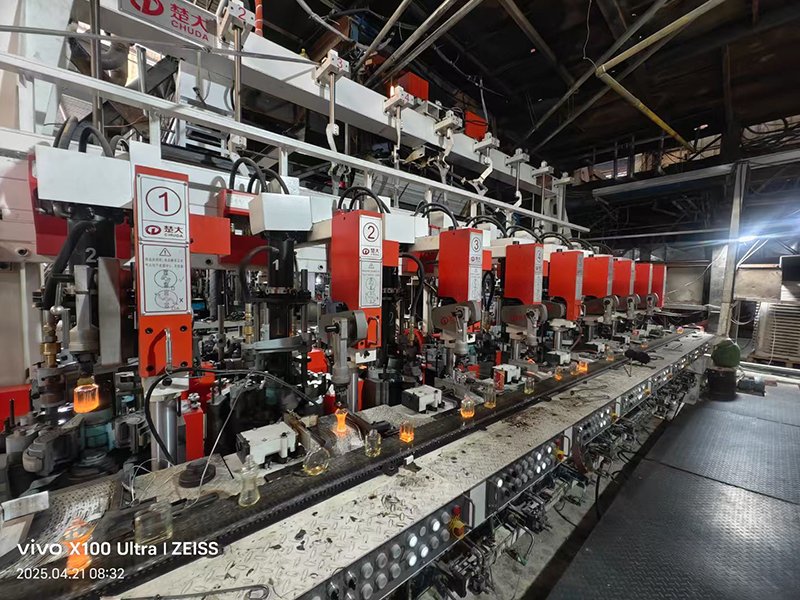

This is where the magic happens. The molten glass is cut into precise gobs (cylinders of molten glass) and fed into forming machines. We primarily use two high-tech methods:

Xuzhou Troy’s advanced IS machines allow us to produce a vast range of jar sizes and styles, from classic Mason jars to sleek, modern containers, all with perfectly consistent neck finishes—a critical factor for reliable sealing.

Newly formed jars are hot and contain internal stresses that would make them fragile. To ensure strength and durability, each jar travels through a carefully controlled oven called an annealing lehr.

The jars are gradually heated and then slowly cooled over a specific temperature curve. This process relieves the internal stresses, making the glass incredibly strong and resistant to thermal shock.

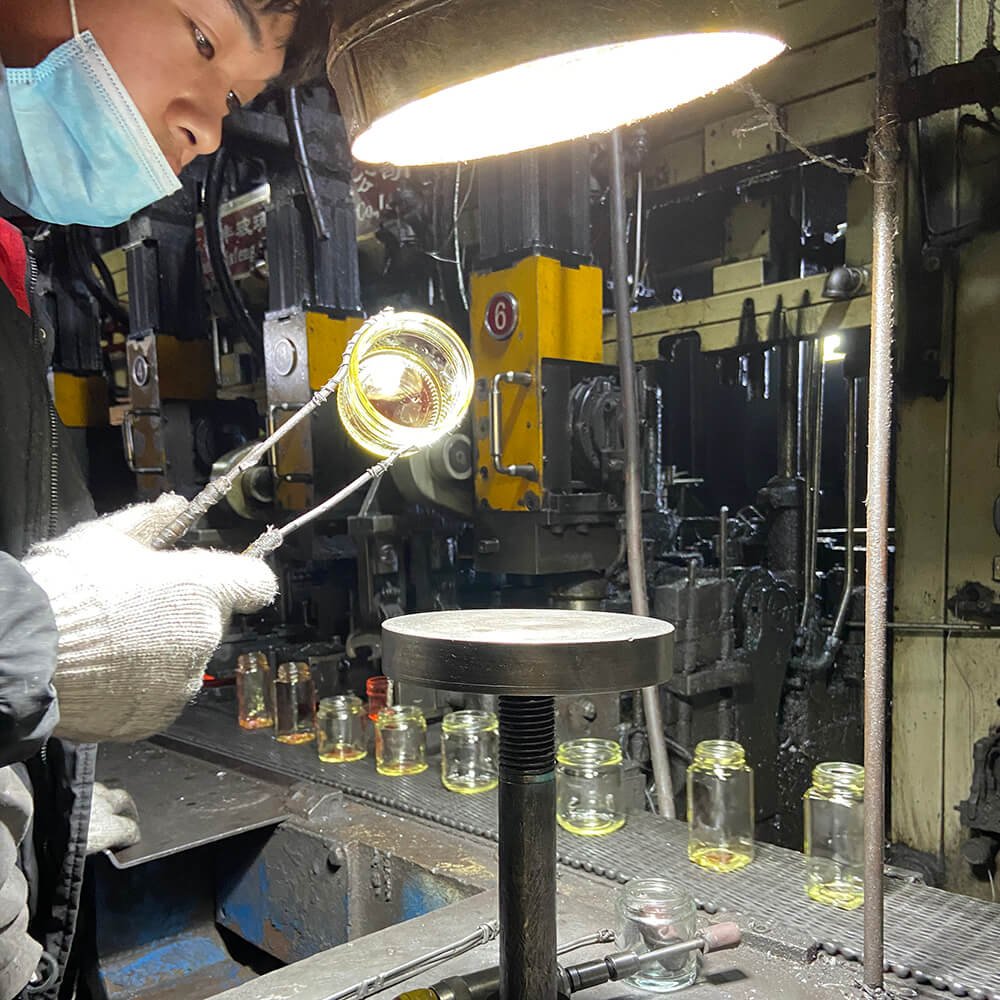

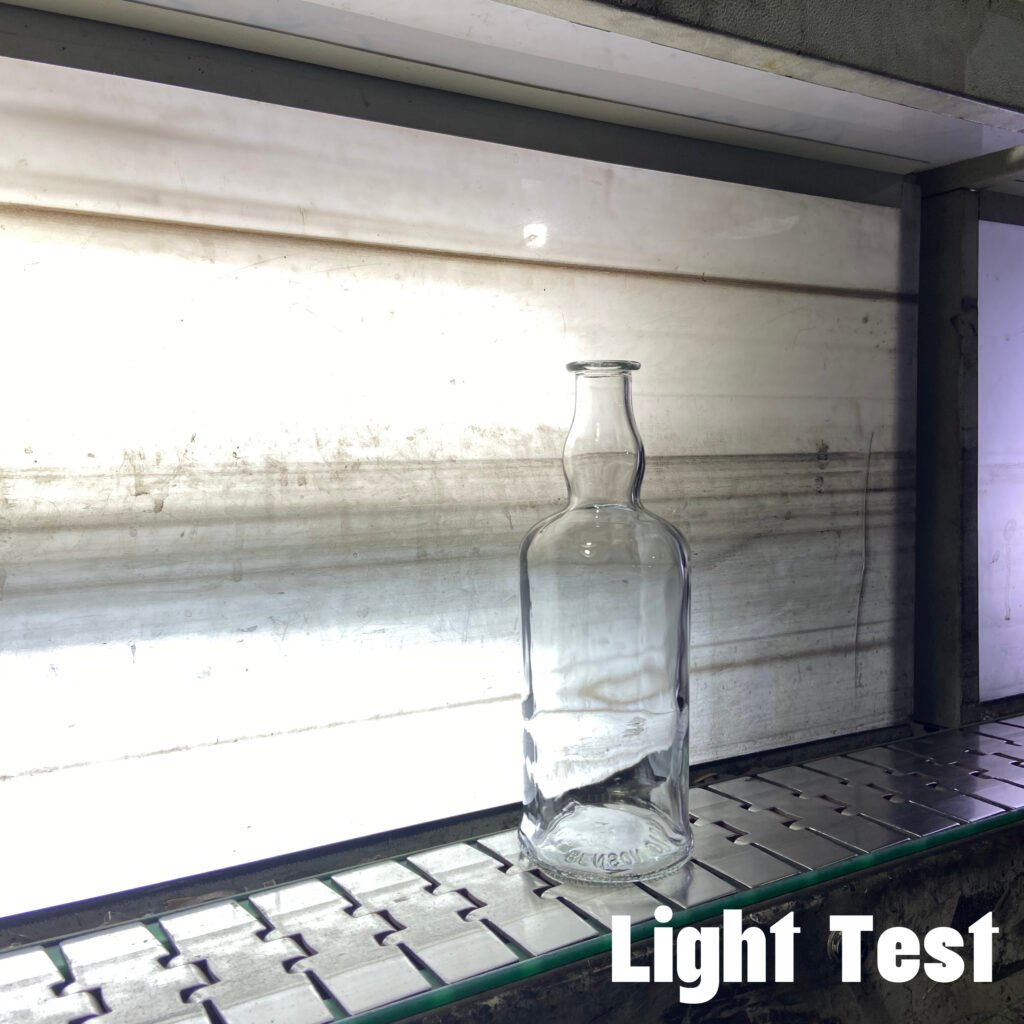

Quality is not an afterthought; it is integrated into every stage. Our automated inspection systems and dedicated QC team perform rigorous checks, including:

Visual Inspection: Checking for bubbles, stones, or imperfections.

Dimensional Checks: Ensuring consistent height, diameter, and, most importantly, thread profile for a perfect seal.

Stress Analysis: Using polarized light to detect any residual stress.

Verticality and Load Testing: Ensuring jars can withstand stacking.

Jars that do not meet our high standards are immediately removed and recycled as cullet.

Choosing Xuzhou Troy means more than just buying glass jars; it means partnering with a manufacturer committed to excellence, sustainability, and innovation at every stage. From the batch house to the final inspection, our process is designed to provide you with a superior packaging solution.

See the quality for yourself.

REQUEST FREE SAMPLES NOW >>

CONTACT OUR TEAM >>

FIND MORE PRODUCTION VIDEOS >>