Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

This article explores two premium glass bottle decoration techniques: silk screen printing for durable, vibrant graphics and hot stamping for luxurious metallic effects. It details the processes, advantages, and ideal applications for each method, highlighting XUZHOU TROY's expertise in transforming glass packaging into distinctive brand assets.

In the realm of premium glass packaging, the final presentation is often defined by the quality of its surface decoration. Secondary processing techniques like silk screen printing and hot stamping transform standard glass bottles into distinctive brand canvases. At XUZHOU TROY, we master these intricate arts, adding significant value and visual identity to every container.

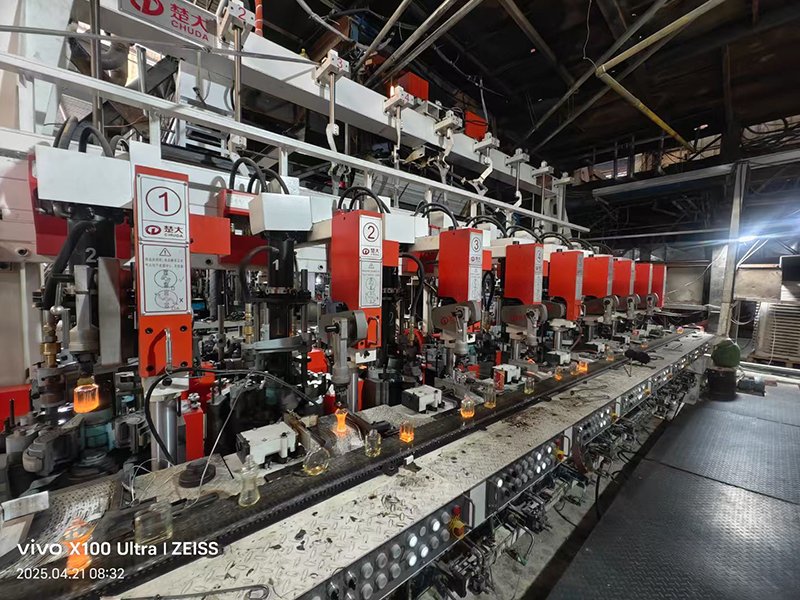

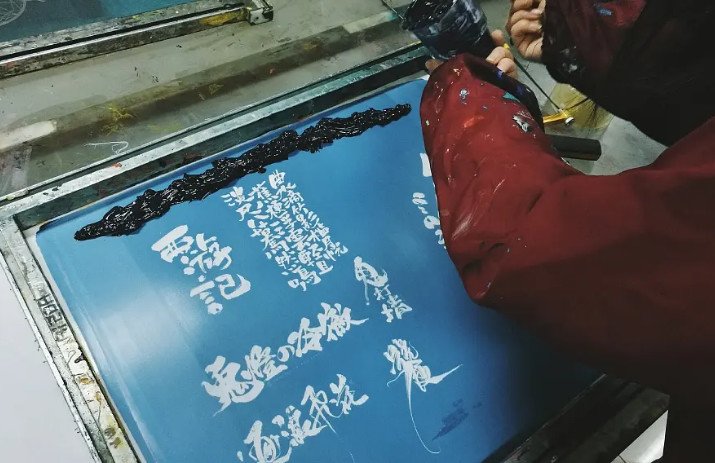

Silk screen printing is a process where ink is forced through a finely woven mesh screen onto a substrate. For glass bottles, this technique creates durable, high-definition graphics with excellent opacity and color vibrancy. The process involves several critical components and meticulous control.

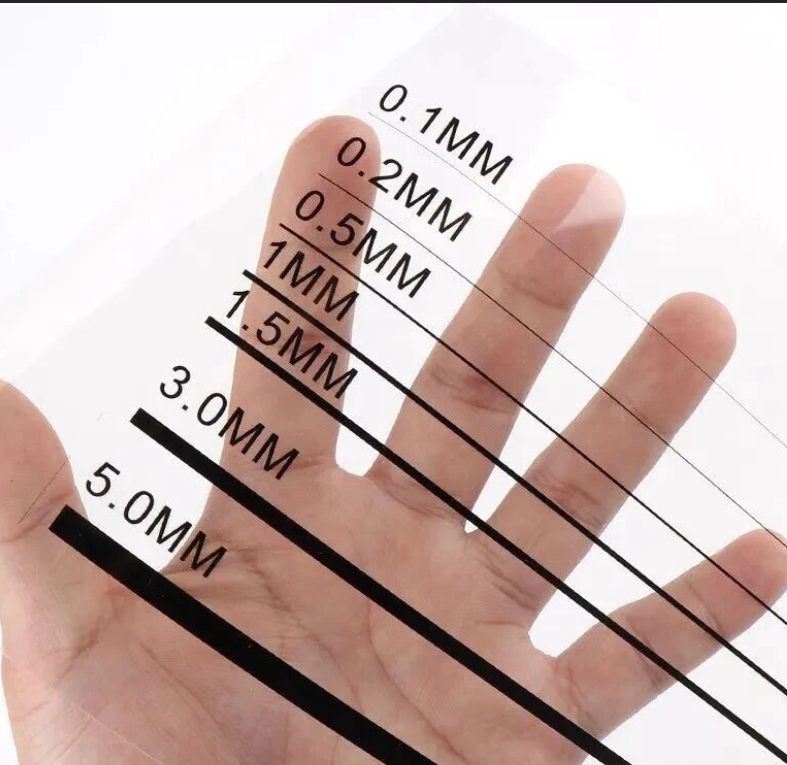

A film positive (or “silk screen film”) is the photographic template of the design. It is used to create the stencil on the mesh screen through a UV exposure process. The precision of this film, measured in lines per inch (LPI, typically 45-65 for glass), directly determines the sharpness and detail of the final print. Modern materials like PVC, PC, and PET films offer high durability and precision.

Our decal tecSpecialized glass screen printing inks are formulated for strong adhesion and chemical resistance. Using a squeegee, the ink is pressed through the open areas of the screen onto the bottle surface. The ink’s viscosity, combined with controlled pressure and angle, determines the deposit thickness and edge definition.hnology accommodates diverse container geometries:

Round, square, triangular, and irregular shapes

Curved surfaces and hard-to-reach areas

Various bottle sizes from miniatures to large-format containers

Durability: Prints are baked at high temperatures, fusing the ink permanently to the glass, making them resistant to washing, handling, and solvents.

Opacity & Color Strength: Excellent for solid colors, bold logos, and high-contrast designs.

Versatility: Can be applied to various glass shapes and surfaces.

Cost-Effectiveness for Medium Volumes: Ideal for runs where digital printing is less economical.

| Issue | Probable Causes | XUZHOU TROY Solutions |

|---|---|---|

| Feathering/Blurred Edges | Incorrect ink viscosity; unsuitable screen mesh; unstable printing speed. | Precisely control ink rheology; select optimal screen mesh count; automate squeegee pressure and speed. |

| Poor Adhesion/Scratches | Inadequate glass surface preparation; incorrect curing temperature/time. | Implement pre-treatment (e.g., plasma or flame treatment) for perfect ink bonding; utilize precisely controlled curing ovens. |

| Ink Bleeding/Smudging | Ink drying time too slow; bottles placed too close before curing. | Use fast-setting inks or UV-curable options where suitable; optimize spacing on curing racks. |

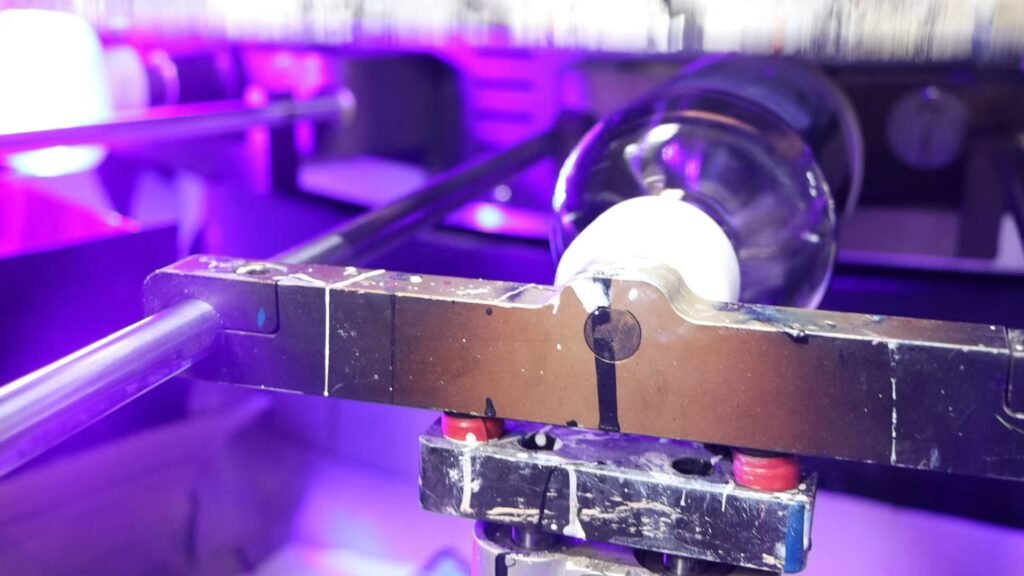

Hot stamping (or foil stamping) is a dry printing process that uses heat and pressure to transfer metallic or pigmented foil from a carrier film onto the glass surface. It creates a brilliant, raised finish that instantly conveys premium quality.

A custom-made metal die (engraved with the design) is heated.

A roll of foil film is positioned between the die and the glass bottle.

Under precise pressure, the hot die presses the foil onto the glass, causing the adhesive layer to bond the metallic/pigmented layer to the surface.

The carrier film is peeled away, leaving the shiny design.

Premium Aesthetic: Creates a luxurious, reflective metallic or glossy color finish unmatched by printing.

Tactile Quality: Produces a slightly raised, elegant texture.

Durability: The foil layer is highly resistant to abrasion and fading.

Design Impact: Ideal for accenting logos, text, or borders to make them “pop.”

Surface Compatibility: Works best on smooth, curved surfaces. Complex textures can be challenging.

Die Cost: Requires the fabrication of a brass or silicon die, making it more suitable for established designs and medium-to-large production runs.

Foil Selection: A vast range of foils is available—gold, silver, holographic, matte, pigmented colors—allowing for extensive brand customization.

The choice between silk screen printing and hot stamping depends on your brand’s vision, design complexity, and budget.

Choose Silk Screen Printing for: High-opacity colors, complex multi-color graphics, cost-effective medium runs, and designs requiring extreme durability.

Choose Hot Stamping for: Metallic effects (gold, silver, etc.), premium tactile feel, accent detailing on logos or text, and projects where a luxury perception is paramount.

Our technical team can guide you through this selection, often recommending a combination of both techniques on a single bottle for maximum visual impact.

discuss how our silk screen printing and hot stamping capabilities can bring your brand’s vision to life with precision and elegance

CONTACT OUR TEAM >>