Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

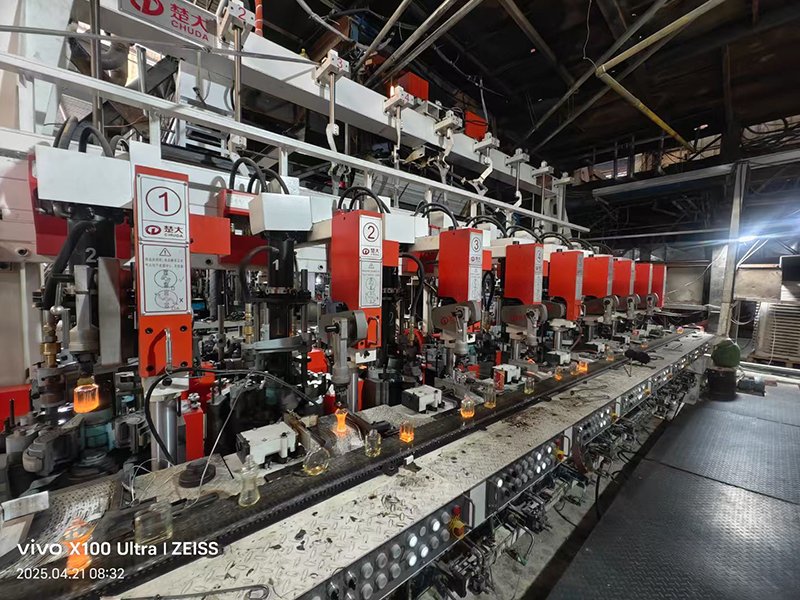

This article examines the practical realities of repairing versus replacing GPI caps in professional packaging applications. It analyzes technical limitations, economic considerations, and performance requirements while presenting XUZHOU TROY's quality-focused approach to closure solutions that prioritize reliability, production efficiency, and brand protection.

In the world of premium packaging, every component matters—including the closure. As a leading supplier in the glass packaging industry, XUZHOU TROY frequently addresses questions about the maintenance and longevity of GPI (Glass Packaging Institute) caps. Understanding whether to repair or replace these essential components is crucial for businesses focused on quality control, cost optimization, and sustainability. This guide examines the practical realities of GPI cap maintenance within the context of modern production environments.

GPI caps represent sophisticated closure systems engineered for specific performance standards. These caps typically feature:

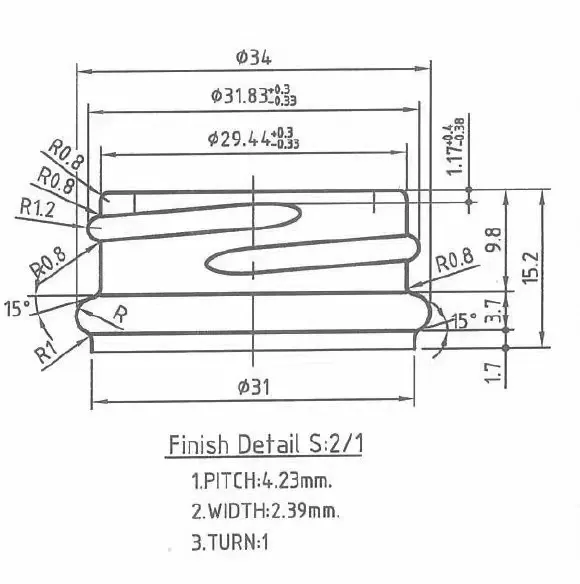

Threaded Engagement Systems: Precision-machined threads designed for consistent torque application and secure sealing

Composite Material Construction: Often combining metal exteriors with polymer or composite liner systems

Sealing Mechanisms: Advanced liners (foam, pulp, plastisol) that create hermetic or tamper-evident seals

Decorative Elements: Embossed logos, printed graphics, or specialty finishes that contribute to brand presentation

At XUZHOU TROY, we recognize that these caps are integral to the complete packaging solution—they’re not merely functional components but brand touchpoints that influence consumer perception.

Material-Specific Challenges:

Metal Components: While minor surface scratches might be cosmetically addressable, structural damage to threads or sealing surfaces typically compromises the cap’s functional integrity beyond practical repair

Polymer Elements: Plastic components may develop stress fractures or deformation that cannot be reliably restored to original performance specifications

Liner Systems: Once compromised, sealing liners cannot be effectively replaced outside factory conditions

Performance Considerations:

Seal Integrity: Even visually successful repairs often fail to restore the original sealing performance, risking product contamination or spoilage

Torque Consistency: Repaired caps rarely maintain the precise torque specifications required for automated filling lines

Sanitation Compliance: Repair processes may introduce contaminants or create surfaces that cannot be properly sanitized

Economic Analysis:

Direct Costs: Repair materials, specialized tools, and skilled labor often exceed the unit cost of replacement caps

Indirect Costs: Production downtime, quality control failures, and potential product loss frequently outweigh any theoretical savings

Scale Considerations: While individual repair might seem viable for very small operations, production-scale environments require consistent, reliable components

Rather than focusing on repair, we recommend a preventative strategy:

1. Quality-First Sourcing:

Our GPI caps are manufactured to exacting specifications, ensuring:

Consistent thread engagement and torque performance

Durable materials resistant to typical handling stresses

Reliable sealing systems verified through rigorous testing

2. Proper Application Guidelines:

We provide comprehensive technical support covering:

Correct torque specifications for different bottle types

Equipment calibration and maintenance protocols

Staff training for proper cap application techniques

3. Strategic Inventory Management:

Just-in-time supply arrangements to minimize storage issues

Protective packaging to prevent transit damage

Batch consistency verification before production integration

Certain conditions absolutely necessitate replacement:

Critical Damage Indicators:

Thread Stripping or Cross-threading: Compromises sealing and creates production line issues

Liner Detachment or Degradation: Directly affects product preservation

Structural Deformation: Alters cap dimensions and performance characteristics

Corrosion or Chemical Attack: Particularly relevant for caps used with acidic or alkaline products

Operational Requirements:

Automated Production Environments: Require absolute consistency in cap dimensions and performance

Regulated Industries (Food, Pharma): Mandate traceable, verifiable component integrity

Premium Brand Positioning: Demand flawless visual presentation and performance

We position ourselves as packaging partners rather than mere suppliers:

Technical Consultation:

Cap selection guidance based on specific product characteristics

Compatibility testing with different bottle finishes

Production line optimization recommendations

Quality Assurance:

Rigorous incoming inspection protocols

Batch testing for consistency and performance

Documentation and certification support

Sustainability Integration:

Recyclable material options aligned with circular economy principles

Lightweighting opportunities to reduce material use

Take-back program exploration for certain applications

While the concept of repairing GPI caps might appear economically attractive initially, the realities of performance requirements, production efficiency, and brand protection typically make replacement the only viable option for professional applications. The marginal savings from repair attempts rarely justify the risks of product compromise, production disruption, or brand reputation damage.

At XUZHOU TROY, we believe in providing closure solutions that deliver reliability from the first application through the product’s complete lifecycle. By focusing on quality manufacturing, proper application, and strategic inventory management, businesses can achieve superior results without resorting to problematic repair strategies.

CONTACT OUR TEAM >>