Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

This article details the sophisticated preparatory science behind high-quality spray-painted glass packaging, covering surface cleaning, environmental control, coating preparation, precision fixturing, and equipment calibration that collectively determine the final finish quality.

While the final spray-painted finish captures immediate attention, the true determinant of quality in glass packaging occurs long before any paint touches the surface. In the glass packaging industry, up to 70% of the final aesthetic and functional outcome depends on meticulous preparation. What appears as a simple decorative process is, in reality, a sophisticated scientific operation conducted on an “invisible battlefield” where precision dictates performance. At XUZHOU TROY, we understand that excellence is built in the preparatory stages. Here are the five critical, scientifically grounded steps that ensure a flawless, durable, and premium coating.

A pristine surface is non-negotiable. The journey begins with removing contaminants invisible to the naked eye.

Ultrasonic Deep Cleaning: Components undergo ultrasonic baths that use high-frequency sound waves to create cavitation bubbles. These bubbles implode, generating microscopic scrubbing action that dislodges grease, dust, and residues at a submicroscopic level. The purity of the water is paramount, with resistivity rigorously controlled at ≥15 MΩ·cm to prevent ionic contamination.

Plasma Activation: Following cleaning, glass surfaces are treated with plasma—a state of matter where gas is ionized by high-frequency energy. This process increases the surface energy from around 40 mN/m to over 70 mN/m, transforming the molecular landscape of the glass. This “activation” creates optimal bonding sites, ensuring the coating achieves molecular-level adhesion for unmatched durability and chip resistance.

The coating environment itself is a critical variable, controlled to laboratory-grade standards to eliminate defects.

Cleanroom Integrity: Spray booths operate in environments meeting Class 10,000 cleanroom standards (≤352,000 particles ≥0.5μm per cubic meter). This prevents airborne dust from embedding itself in the wet paint, a primary cause of visual defects.

Climatic Precision: Temperature and humidity are locked at 23±2°C and 55±5% RH. Even minor fluctuations can alter coating viscosity, flow, and curing kinetics. This stability is the cornerstone of achieving consistent color and texture batch after batch.

Laminar Airflow Design: A vertical laminar airflow system creates a gentle, downward “air curtain.” This constant, clean air movement carries away overspray and prevents the settling of any ambient particles onto freshly painted surfaces.

The paint itself is treated as a precision material, with its properties meticulously calibrated.

Viscosity Control: Using calibrated rotational viscometers, the coating’s viscosity is maintained within ±5% of its target value. This ensures consistent atomization through the spray gun and uniform film leveling on the glass.

Multi-Stage Filtration: Before reaching the spray gun, the coating passes through a progressive three-stage filtration system (10μm → 5μm → 1μm). This removes any undissolved pigments, micro-gels, or other impurities that could clog nozzles or create surface imperfections.

Homogenization & Degassing: Coatings are electrically stirred for a minimum of 30 minutes prior to use. This achieves perfect homogenization of components and removes entrained air bubbles, ensuring optimal leveling properties and a defect-free film.

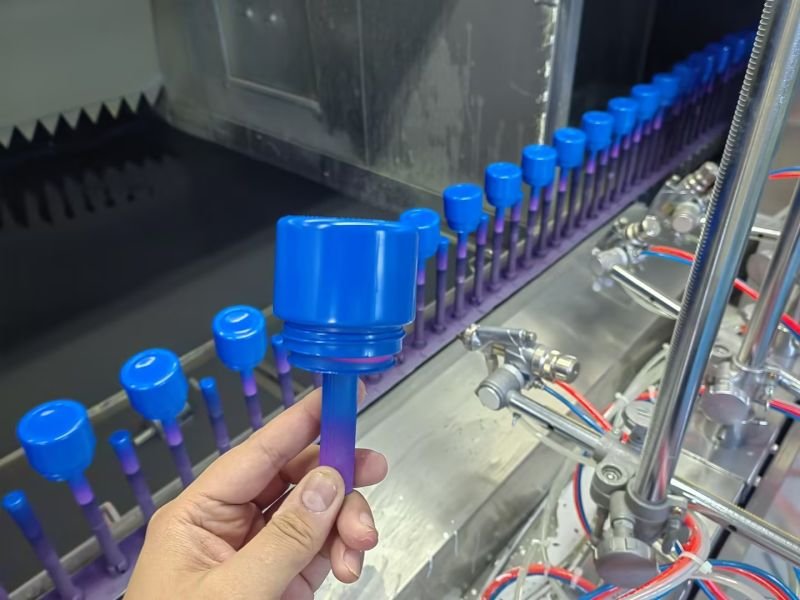

How the glass is held and protected is as important as how it is painted.

Custom Engineered Fixtures: Each bottle or jar design requires dedicated fixtures. These fixtures provide secure, stable holding while maintaining a precise ~0.2mm gap between the glass and the fixture. This gap allows for slight paint overflow (flash) without creating build-up or “paint bridges” that could lock the piece in place.

Millimeter-Accurate Masking: Critical functional areas like threaded finishes, sealing lips, or internal surfaces are protected using high-temperature resistant tapes and masks. This millimeter-level precision ensures paint only goes where it’s designed to, preserving functionality and avoiding post-process cleanup.

Static Elimination: Ionizing bars are strategically installed to neutralize static charge on glass surfaces. Static is a powerful magnet for airborne dust; eliminating it is crucial for maintaining the cleanliness achieved in the cleanroom.

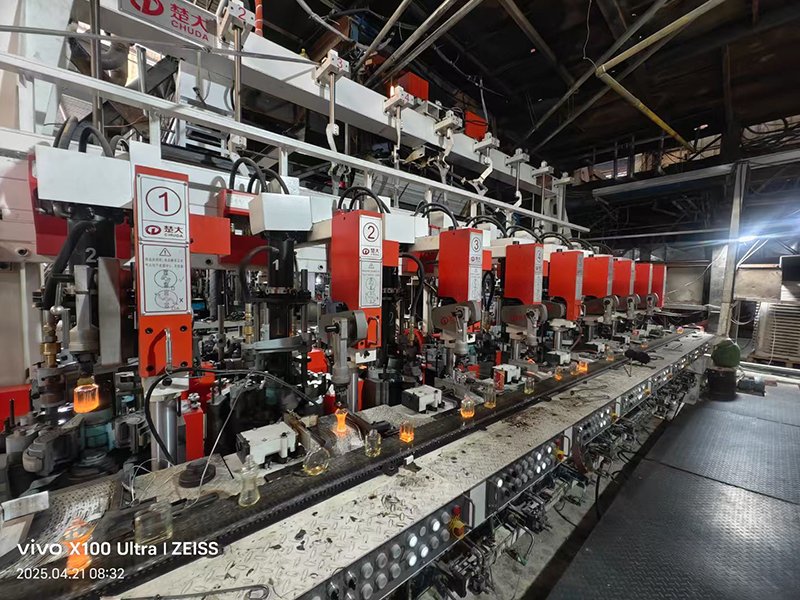

No production run begins without a full system audit to ensure every parameter is within specification.

Spray Gun Calibration: Atomization pressure, fan air pressure, electrostatic voltage, and fluid flow are verified. Deviations for each parameter must be ≤1.5% from their setpoints to guarantee a consistent spray pattern and deposition rate.

Conveyor Speed Stability: The speed of the conveyor carrying pieces through the spray zone is controlled with an error margin of ±0.1 meters per minute. This directly controls the exposure time and, consequently, the final film thickness.

First-Article Validation: Before full production, a sample piece is coated, cured, and measured using precision micrometers. This “first-piece inspection” validates that the entire prepared system—from environment to equipment to material—is delivering the exact target dry film thickness (DFT).

At XUZHOU TROY, we view spray painting not as a mere decoration step, but as a critical technical discipline. Our investment in advanced preparation technologies—from plasma treaters to climate-controlled cleanrooms and precision calibration tools—is a testament to our philosophy: The unseen work defines the seen quality.

We partner with brands that refuse to compromise, providing them with glass packaging whose beauty is backed by unwavering scientific rigor. The result is a finish that looks impeccable, feels premium, and stands the test of time—a true reflection of your brand’s standards.

REQUEST FREE SAMPLES NOW >>

CONTACT OUR TEAM >>

FIND MORE PRODUCTION VIDEOS >>