Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Glass is a premier packaging material, but not all glass is created equal. This article breaks down the three main classifications of glass used for containers (Type I, II, and III). We focus on Soda-Lime Glass (Type III), the most widely used and cost-effective option for products ranging from Mason jars to beverages. We explore its chemical composition—silica, soda ash, and lime—and detail the key reasons for its dominance in the consumer packaging industry: chemical inertness, versatility, and 100% recyclability.

When you reach for a jar of preserves, a bottle of wine, or a cosmetic container, you are interacting with one of the world’s most enduring and reliable packaging materials: glass. For centuries, glass has been the preferred choice for preserving and protecting various products due to its inertness, barrier properties, and aesthetic appeal.

While glass may seem monolithic, there are actually several distinct types used in packaging, each formulated for specific applications. Understanding these differences, particularly the dominance of Soda-Lime Glass, is key to appreciating the packaging industry.

The glass used for containers and bottles is typically classified into three main types based on its chemical composition:

Type I (Borosilicate Glass): Often called “lab glass,” this type contains boron oxide, which gives it superior resistance to thermal shock and chemical leaching. It is the most chemically inert and durable type of glass.

Common Use: Pharmaceuticals, highly reactive chemicals, and laboratory equipment.

Type II (Treated Soda-Lime Glass): This is regular soda-lime glass that has been surface-treated (de-alkalized) in a process called “sulfur treatment” to increase its chemical resistance, especially against water attack.

Common Use: Certain injectable medications and infusions.

Type III (General Purpose Soda-Lime Glass): This is the most common and economical type of glass. It is suitable for most non-parental preparations (non-injections) and is the workhorse of the consumer packaging world.

The vast majority—approximately 90%—of all glass used in packaging, from your favorite Mason jars to beverage bottles, is Soda-Lime Glass (Type III). It is the most practical choice due to its excellent balance of cost-effectiveness, strength, and ease of recycling.

Soda-lime glass is an amorphous (non-crystalline) solid primarily composed of three raw materials, melted and fused at extremely high temperatures:

Silica(~70-74%): Derived from sand, this is the main structural component, providing the basic glassy network.

Soda Ash(~12-16%): This acts as a ‘flux,’ lowering the high melting temperature of silica, which makes the glass-making process more economical and efficient.

Limestone & Dolomite (~10-12%): These add the essential ingredient calcium oxide (the ‘lime’) which stabilizes the glass, making it durable and resistant to water.

Characteristics:

Transparency: Excellent clarity for product visibility

Durability: Good mechanical strength and thermal resistance

Cost-Effective: Economical production and widely available

Recyclable: Fully compatible with glass recycling systems

Common Applications:

Food and beverage containers (jars, bottles)

Pharmaceutical packaging

Cosmetic containers

General household glassware

For a company like XUZHOU TROY, which specializes in packaging, soda-lime glass offers compelling advantages, our standard Mason jars, beverage bottles, and food containers primarily use high-quality soda-lime glass for optimal balance of performance and value.:

Chemical Inertness: It does not react with the contents—be it food, beverages, or cosmetics—preserving the flavor, purity, and integrity of the product.

Versatility: It can be molded into countless shapes and sizes, resulting in everything from our classic Mason jars to complex cosmetic bottles.

High Barrier Properties: It provides an excellent, hermetic barrier against gases, moisture, and odors, giving products a long shelf life.

Aesthetics: It offers clarity (in flint/clear glass), allowing the product to be seen, and can be colored (amber, green, blue) to provide UV protection.

Sustainability: Soda-lime glass is 100% and infinitely recyclable without loss of quality. Using recycled glass (cullet) in manufacturing significantly reduces energy consumption.

Known for its exceptional thermal and chemical resistance, borosilicate glass represents the premium segment of glass packaging.

Composition:

Silica sand (70-80%)

Boron trioxide (10-13%)

Alkali oxides (7-13%)

Key Advantages:

Thermal Shock Resistance: Withstands sudden temperature changes up to 160°C difference

Chemical Inertness: Highly resistant to acids, alkalis, and solvents

Dimensional Stability: Maintains shape under stress and temperature variations

Enhanced Durability: Higher mechanical strength than standard glass

Typical Uses:

Laboratory glassware

Pharmaceutical vials and ampoules

Premium kitchenware (oven-safe containers)

High-end cosmetic and perfume packaging

Specialized food packaging for extreme conditions

XUZHOU TROY Application:

We utilize borosilicate glass for specialty products requiring superior thermal performance, such as containers for hot-filled products or premium cosmetic lines.

While Type I glass is crucial for specialized medical applications, Soda-Lime Glass (Type III) is the workhorse that powers the global packaging industry. Its strength, cost-efficiency, and unmatched recyclability make it the ideal material for XUZHOU TROY’s high-quality Mason jars, food storage containers, and beverage bottles.

Choosing glass for your packaging is a choice for quality, sustainability, and time-honored preservation.

Consider These Factors:

Product Compatibility

Chemical compatibility with contents

Temperature requirements (processing and storage)

Light sensitivity needs

Brand Positioning

Premium vs. mainstream positioning

Transparency vs. UV protection requirements

Aesthetic preferences and brand colors

Functional Requirements

Strength and durability needs

Processing requirements (hot filling, pasteurization)

Shipping and handling conditions

Sustainability Goals

Recyclability considerations

Weight optimization for transportation

Reusability potential

Cost Considerations

Material costs versus performance benefits

Production volume requirements

Specialized processing needs

Our expertise in glass packaging includes:

Material Selection Guidance: Helping clients choose the optimal glass type for their specific needs

Quality Assurance: Rigorous testing of all glass materials for performance and safety

Custom Solutions: Developing specialized glass formulations for unique applications

Sustainability Focus: Optimizing glass selection for environmental performance

Technical Support: Ongoing consultation throughout product development

Whether you need standard soda-lime containers for food products, borosilicate glass for technical applications, or customized solutions for luxury branding, we provide comprehensive support from material selection through final production.

REQUEST FREE SAMPLES NOW >>

CONTACT OUR TEAM >>

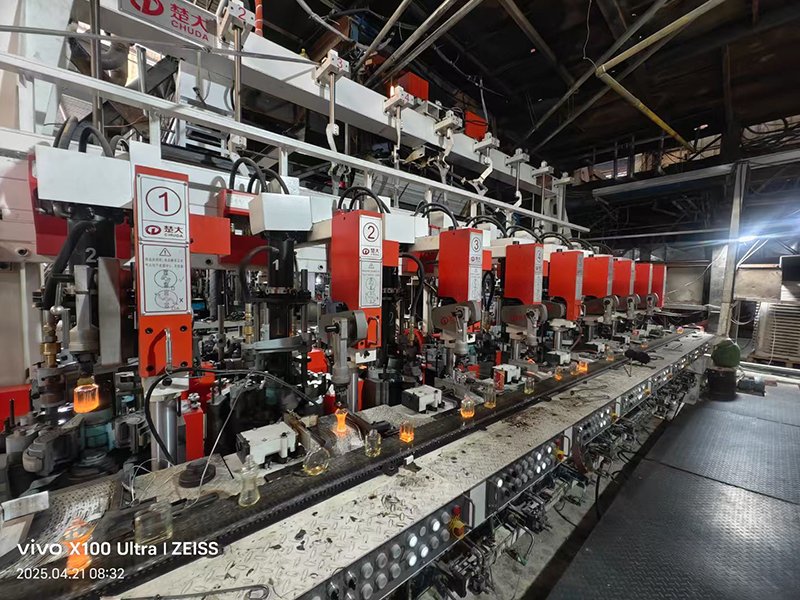

FIND MORE PRODUCTION VIDEOS >>