Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

In the glass container manufacturing industry, the selection of production processes and equipment directly impacts product quality, efficiency, and cost. As a leading provider of glass packaging solutions, Xuzhou Troy is committed to delivering high-quality products through advanced production technology and equipment. This article provides a detailed introduction to the three core machines used in glass container production—IS Machines, Press Machines, and Hand-operated Machines—with a focus on their characteristics, suitable product types, and Minimum Order Quantity (MOQ) requirements, offering professional guidance for procurement specialists.

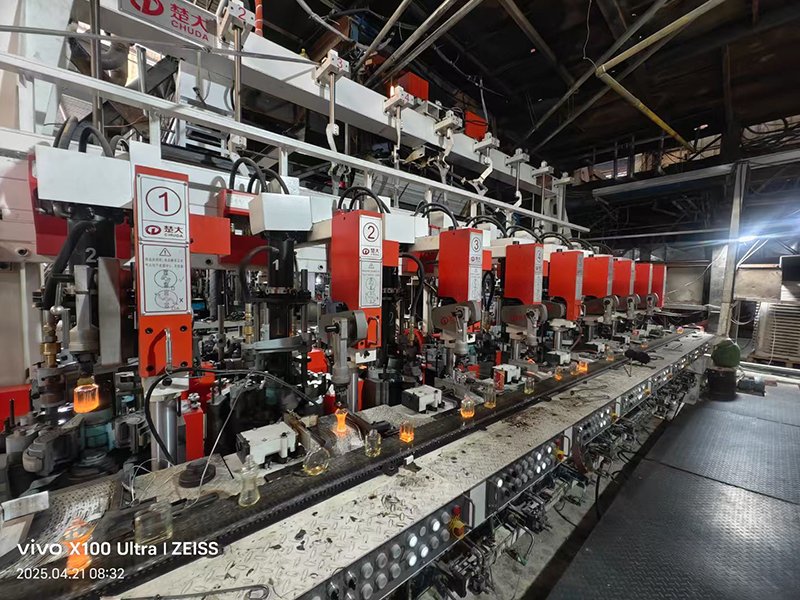

IS (Individual Section) Machines are the most widely used automated equipment in glass container production. They form containers through a sequential process, offering high efficiency and stability. Based on the number of gobs, IS Machines can be classified into Single Gob, Double Gob, and even Multi-Gob models (e.g., Quad, Six, and Eight Gob).

High Production Efficiency: Double Gob and Multi-Gob models can produce multiple containers simultaneously, significantly increasing output.

Flexibility and Adaptability: Different container specifications can be produced by simply changing molds, meeting diverse market needs.

Mature and Stable Process: Utilizing the Blow-Blow method (for small-neck containers) or Press-Blow method (for wide-mouth containers), ensuring uniform wall thickness and an aesthetically pleasing finish.

Single Gob IS Machines: Ideal for containers with a capacity above 250 ml, such as beverage bottles and food jars. Common configurations in China are 6-Section Single Gob (6S) or 8-Section Single Gob (8S).

Double Gob IS Machines: Suitable for containers with a capacity of 50-250 ml, such as sauce bottles and medicine vials. Common configurations include 6-Section Double Gob (6D) or 8-Section Double Gob (8D).

Multi-Gob IS Machines: For ultra-small containers (5-50 ml), such as perfume bottles and sample vials, 3-Gob, 4-Gob, or even 6-Gob machines are available. However, these require significantly larger order volumes.

For Single Gob and Double Gob machines, the typical MOQ ranges from 50,000 to 100,000 pieces, depending on the complexity of the container design.

For Multi-Gob machines, due to higher setup and debugging costs, the MOQ generally starts from 500,000 pieces.

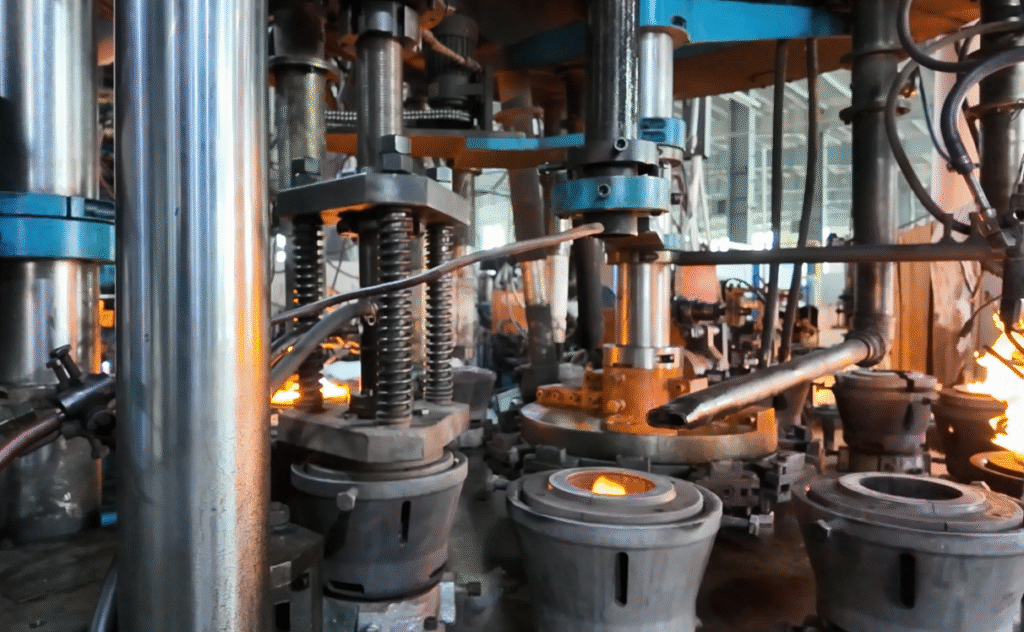

Press Machines form containers by pressing molten glass into a mold, making them suitable for products with thicker walls and simpler shapes.

Key Features and Advantages

Suitable Product Types

MOQ Requirements

Hand-operated Machines rely on skilled artisans for manual blowing and shaping, making them ideal for personalized and high-end custom products.

Key Features and Advantages

High Flexibility: Capable of producing containers with complex designs, such as irregular shapes and embossed patterns.

High Artistic Value: Each piece possesses a unique, handcrafted quality.

Suitable Product Types

Premium liquor bottles, art pieces, commemorative items, and other niche custom products.

MOQ Requirements

Due to lower production efficiency and reliance on manual labor, the MOQ is typically between 500 and 2,000 pieces, suitable for small-batch, high-end orders.

The forming process in IS Machines is divided into two main methods based on product requirements:

Blow-Blow Process: Primarily used for small-neck containers (e.g., beverage bottles). It involves two blowing stages to ensure precision in the body and finish (the threaded part).

Press-Blow Process: Suitable for wide-mouth containers (e.g., food jars). It involves pressing the finish first and then blowing the body, ensuring a smooth rim and excellent seal.

Xuzhou Troy’s IS Machine production lines are equipped with intelligent temperature control systems and automatic mold lubrication devices, guaranteeing stable dimensions and a flawless, glossy surface finish on every container.

Selecting the right production equipment is crucial for balancing cost, efficiency, and quality. Xuzhou Troy operates multiple advanced production lines, including IS Machines, Press Machines, and Hand-operated Machines, providing comprehensive solutions from standard to fully custom containers. Whether for large-scale procurement or niche customization, we offer professional technical support and flexible MOQ requirements to meet your diverse needs.

For more information about our machinery and production capabilities, please contact the Xuzhou Troy team for a professional consultation!

REQUEST FREE SAMPLES NOW >>

CONTACT OUR TEAM >>

FIND MORE PRODUCTION VIDEOS >>